PRODUCT

FINISHING

WHAT WE DO

In most cases a protective coating system is chosen to increase the durability of a project that is at risk from severe corrosion in an aggressive environment. With over 40 years’ experience in Product Finishing services, we commit to our quality assurance of surface protection. As a local coating industry based in the North-West of England, we understand the importance of the life time and durability of structural fabrications. This is why our in house professionals are proficient in airless, conventional and thermal metal spraying and can supply technical coatings adhered to Network Rail and Highway Agencies’ specifications.

Our strict quality control ensures all work is of the highest standard, whether it is as straight forward as a shot blasting and prime or a full aesthetic anti-corrosion system. All of our work is programmed into a production schedule and arranged with you, the client. This enables us to complete complicated multi-coat systems on time, every time to a high degree of competency and reliability.

SERVICES

PROTECTIVE COATING SYSTEMS

Paint is the most frequently used material to protect steelwork and structures that are susceptible to corrosion. The term, ‘paint’ covers a wide range of materials with different properties, some coatings can provide increased protection in immersed environments whilst others can withstand harsh chemical exposure from acids and alkalis.

THERMAL METAL SPRAYING

Thermal metal spraying, commonly referred to as ‘metal spraying’ is an advanced anti corrosion coating that also provides additional wear resistance and electrical conductivity through the use of materials such as; aluminium, zinc and ceramic. This type of coating and process is normally reserved for advanced coating systems that require additional protection or an extended service life.

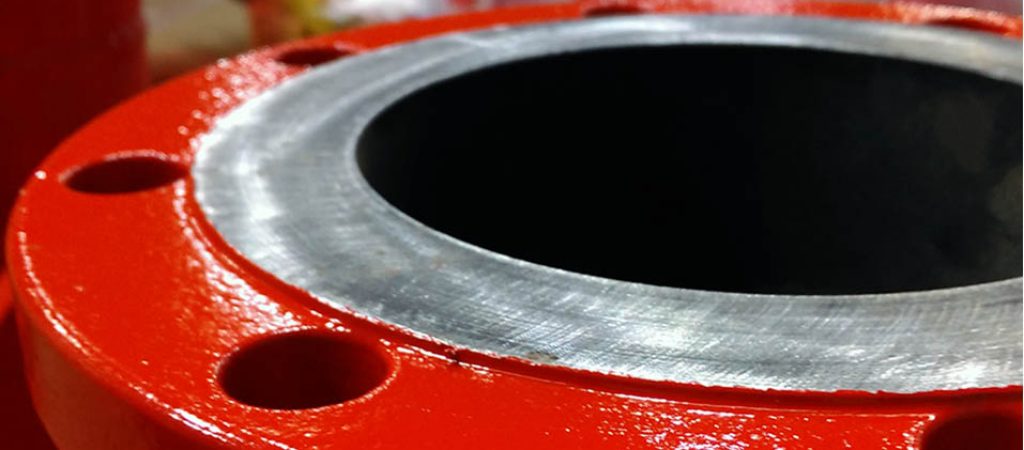

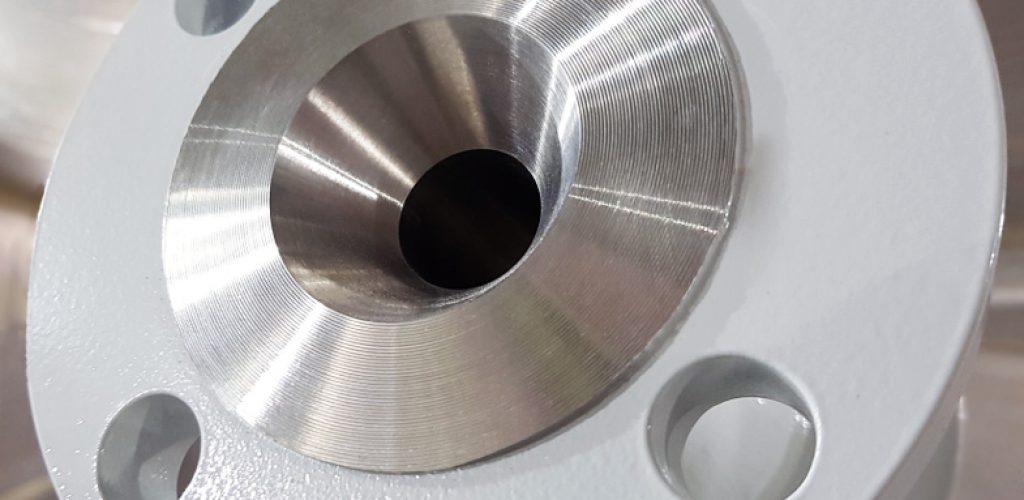

SURFACE PREPARATION

There are many different types of surface preparation ranging from water-jet blasting to machine blasting. The Product Finishing team uses a method called ‘shot/grit blasting’, commonly referred to as ‘sandblasting’. This method involves the blasting media (chilled iron grit or steel shot) being pneumatically forced through a small orifice using compressed air.

AIRLESS SPRAY

Airless spraying works by hydraulically compressing the paint and releasing it through a small orifice which atomises the coating and projects it. By changing the orifice size and shape and by varying the hydraulic pressure, atomisation can be accomplished for a wide range of paint consistencies from thin to thick, to give a wide range of rates of deposition.

QUALITY ASSURANCE

Quality Assurance is of vital importance within NL Williams Group. No matter the size of the project, we strive to produce quality work and services throughout. Our in-house quality assurance department plays a key role making sure we adhere to both the industry’s strict control measures and our own pre-established procedures.

COATING INSPECTION & TESTING

Our quality assurance team are ble produce inspection test plans and project specific documentation to ensure your project is processed to the highest standard. Our inspection reports and supporting documentation can also be customised to suit your individual requirements including; soluble salt tests, MEK tests, visual assessments of surface cleanliness, surface profiles, dry/wet film thickness’, coating batch numbers, all of which are recorded and tested with certified Elcometer® equipment.

PROJECT MANAGEMENT & SUPPORT

We believe that support and communication are as important as the project itself and aim to put you, the client, at the centre of our organisation. Taking your programme and collection dates into consideration, the Production Department will ensure your project is completed on time, to the highest quality and keep you updated throughout.

MORE FROM NL WILLIAMS GROUP

LATEST NEWS

Leicester Tigers Link Bridge

Facebook Twitter Linkedin The newly fabricated link bridge connecting the Hotel Brooklyn and the Leicester Tigers Welford Road Stadium has been installed this week. Featuring […]

Possible supply disruption

Because of severe global raw material shortages and disruptions with supply chains, we are currently experiencing both delivery delays and cost increases on protective coatings, […]

Tower of Light

From the industrial revolution to Manchester’s contributions to music, engineering, and architecture, Manchester has been a hub for change and innovation in the UK. 2020 […]