BEAD BLASTING

NL Williams Group - Bead Blasting Specialists for over 40 years

NL Williams Group operates with two bead blasting booths for the cleaning and protecting of nonferrous equipment. Our bead blasting booths can accommodate a diverse range of projects including; stainless steel vessels, aluminium frames, pressure vessels, water tanks within our lifting capacity of 20 tonnes.

What is bead blasting?

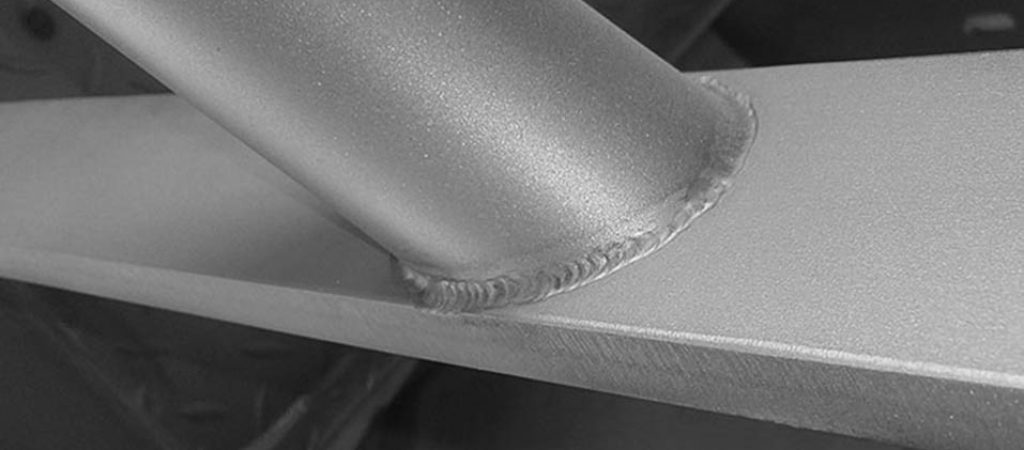

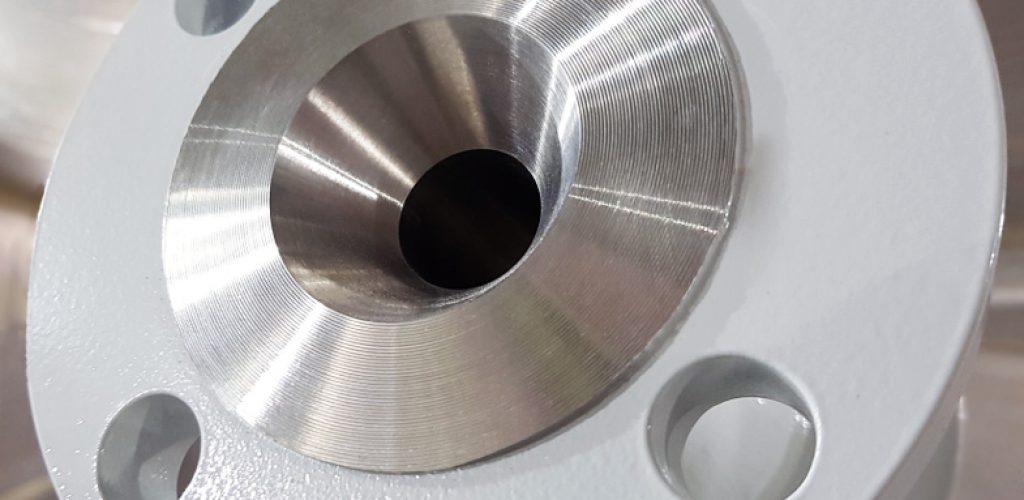

Bead blasting involves discharging fine glass beads using compressed air, to remove imperfections, weld marks and contaminants without damaging the non-ferrous substrate. Bead blasting creates a uniform, non directional matte finish that is much more cost and time effective than polishing.

SERVICES

BEAD BLASTING

Bead blasting is a process designed to remove imperfections and contaminants by applying fine glass beads at a high pressure, without damaging the substrate. It is used to remove contaminants and improve the finish of stainless steel, aluminium or copper materials and can restore equipment back to their original condition.

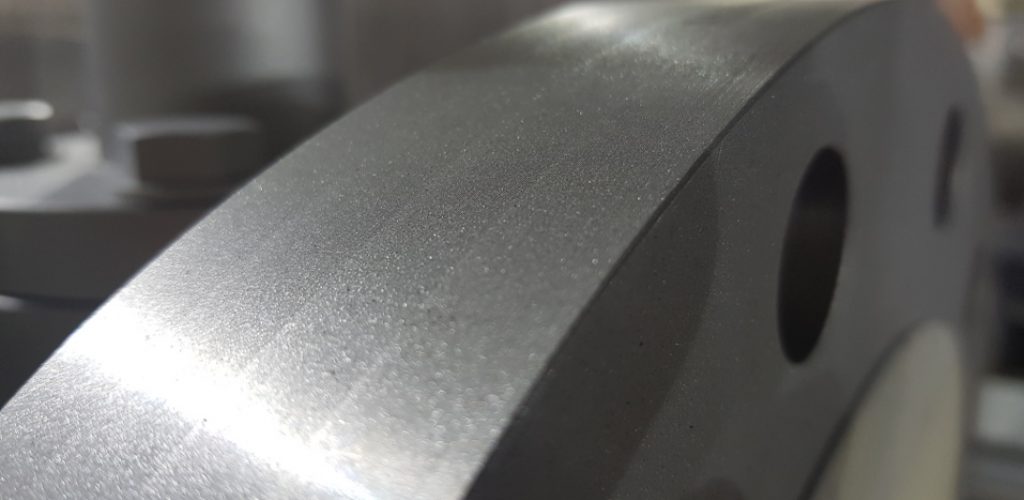

PROTECTIVE LACQUERS

Protective lacquers can provide additional protection for bead blasted steelwork. The thin film lacquer provides excellent exterior durability and prevents oil marks from handling and helps to keep its matte finish.

QUALITY ASSURANCE

Quality Assurance is vitally important to NL Williams Group. No matter the size of the project, we strive to produce quality work and services throughout. Our in-house quality assurance department plays a key role in making sure we adhere to both the industry’s strict control measures and our own pre-established procedures.

PROTECTIVE COATING SYSTEMS

Although materials such as stainless steel & aluminium have excellent anti-corrosive properties on their own. In some industries, this is not enough.

Environments with high salt levels, pollution and aggressive chemicals can severely affect the durability of equipment. Applying a multi-coat, protective paint system will improve performance and reliability of equipment in these harsh environments. See our Product Finishing section for more information.

MORE FROM NL WILLIAMS GROUP

LATEST NEWS

Leicester Tigers Link Bridge

Facebook Twitter Linkedin The newly fabricated link bridge connecting the Hotel Brooklyn and the Leicester Tigers Welford Road Stadium has been installed this week. Featuring […]

Possible supply disruption

Because of severe global raw material shortages and disruptions with supply chains, we are currently experiencing both delivery delays and cost increases on protective coatings, […]

Tower of Light

From the industrial revolution to Manchester’s contributions to music, engineering, and architecture, Manchester has been a hub for change and innovation in the UK. 2020 […]